HST Purlins and Girts are roll formed from zinc coated high-tensile steel Z275, punched in-line and cut to length. Heavier zinc coating weight of Z450 can also be provided on request, subject to minimum order quantity and lead times.

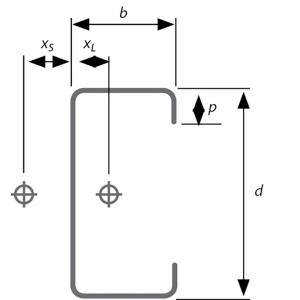

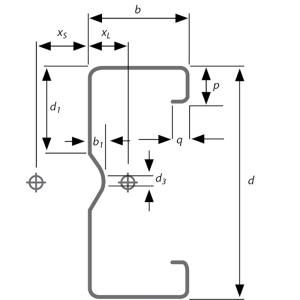

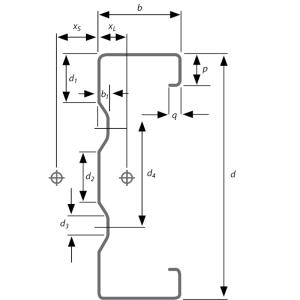

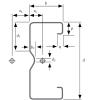

Purlin Profiles

| Profile | Purlin Size HST | d mm | b mm | t mm | p mm | q mm | b1 mm | d1 mm | d2 mm | d3 mm | d4 mm | xL mm | xs mm | Area As mm2 | Mass kg/m |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 100/12 | 102 | 51 | 1.15 | 15 | 16.8 | 24.9 | 253 | 2.03 | ||||||

| 100/15 | 102 | 51 | 1.45 | 15 | 16.6 | 24.7 | 316 | 2.54 | |||||||

| 100/19 | 102 | 51 | 1.85 | 15 | 16.4 | 24.4 | 400 | 3.23 | |||||||

| 150/12 | 152 | 65 | 1.15 | 24 | 10 | 8 | 59 | 7 | 23.5 | 33.3 | 386 | 3.03 | ||

| 150/15 | 152 | 65 | 1.45 | 24 | 10 | 8 | 59 | 7 | 23.2 | 32.9 | 483 | 3.79 | |||

| 150/18 | 152 | 65 | 1.75 | 24 | 10 | 8 | 59 | 7 | 23 | 32.6 | 578 | 4.56 | |||

| 200/12 | 203 | 75 | 1.15 | 25 | 12 | 8 | 59 | 10 | 10 | 48 | 25.1 | 35.2 | 478 | 3.80 |

| 200/15 | 203 | 75 | 1.45 | 25 | 12 | 8 | 59 | 10 | 10 | 48 | 24.9 | 35.1 | 598 | 4.76 | |

| 200/18 | 203 | 75 | 1.75 | 25 | 12 | 8 | 59 | 10 | 10 | 48 | 24.6 | 34.9 | 717 | 5.72 | |

| 250/13 | 250 | 85 | 1.25 | 33 | 12 | 10 | 59 | 14 | 25 | 73 | 28.7 | 37.8 | 625 | 5.01 | |

| 250/15 | 250 | 85 | 1.45 | 33 | 12 | 10 | 59 | 14 | 25 | 73 | 28.6 | 37.7 | 722 | 5.79 | |

| 250/18 | 250 | 85 | 1.75 | 33 | 12 | 10 | 59 | 14 | 25 | 73 | 28.3 | 37.6 | 866 | 6.96 | |

| 300/15 | 300 | 100 | 1.45 | 38 | 12 | 10 | 59 | 64 | 25 | 123 | 32.1 | 45.3 | 847 | 6.72 | |

| 300/18 | 300 | 100 | 1.75 | 38 | 12 | 10 | 59 | 64 | 25 | 123 | 31.9 | 45.1 | 1018 | 8.08 | |

| 300/24 | 300 | 100 | 2.4 | 38 | 12 | 10 | 59 | 64 | 25 | 123 | 31.4 | 44.8 | 1382 | 11.01 | |

| 300/30 | 300 | 100 | 3 | 38 | 12 | 10 | 59 | 64 | 25 | 123 | 30.9 | 44.5 | 1711 | 13.71 | |

| 350/18 | 350 | 100 | 1.75 | 43 | 12 | 10 | 70 | 92 | 25 | 151 | 30.4 | 45.1 | 1123 | 8.96 | |

| 350/24 | 350 | 100 | 2.4 | 43 | 12 | 10 | 70 | 92 | 25 | 151 | 29.9 | 44.8 | 1526 | 12.08 | |

| 350/30 | 350 | 100 | 3 | 43 | 12 | 10 | 70 | 92 | 25 | 151 | 29.5 | 44.5 | 1891 | 15.05 | |

| 400/20 | 400 | 100 | 1.95 | 48 | 12 | 10 | 75 | 132 | 25 | 191 | 29.1 | 45 | 1365 | 10.78 | |

| 400/24 | 400 | 100 | 2.4 | 48 | 12 | 10 | 75 | 132 | 25 | 191 | 28.8 | 44.8 | 1670 | 13.23 | |

| 400/30 | 400 | 100 | 3 | 48 | 12 | 10 | 75 | 132 | 25 | 191 | 28.3 | 44.4 | 2071 | 16.48 |

Notes:

1. All section properties are for the gross section.

2. xL = Centroid xs = Shear Centre.

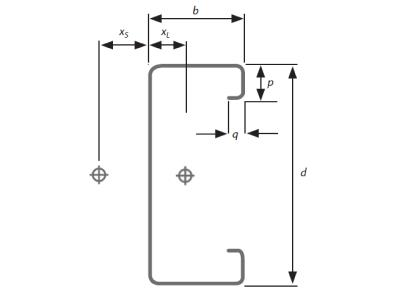

Flatback profile

| Section HST FB | d mm | b mm | t mm | p mm | q mm | xL mm | xs mm | Area As mm2 | Mass kg/m |

|---|---|---|---|---|---|---|---|---|---|

| 150/12 | 152 | 65 | 1.15 | 24 | 10 | 22.77 | 35.16 | 378 | 2.96 |

| 150/15 | 152 | 65 | 1.45 | 24 | 10 | 22.54 | 34.81 | 473 | 3.71 |

| 150/18 | 152 | 65 | 1.75 | 24 | 10 | 22.31 | 34.47 | 567 | 4.44 |

| 200/12 | 203 | 75 | 1.15 | 25 | 12 | 24.19 | 38.30 | 466 | 3.65 |

| 200/15 | 203 | 75 | 1.45 | 25 | 12 | 23.96 | 37.97 | 585 | 4.58 |

| 200/18 | 203 | 75 | 1.75 | 25 | 12 | 23.73 | 37.63 | 702 | 5.50 |

| 250/13 | 250 | 85 | 1.25 | 33 | 12 | 27.22 | 43.77 | 610 | 4.78 |

| 250/15 | 250 | 85 | 1.45 | 33 | 12 | 27.07 | 43.56 | 705 | 5.53 |

| 250/18 | 250 | 85 | 1.75 | 33 | 12 | 26.85 | 43.23 | 847 | 6.64 |

| 300/15 | 300 | 100 | 1.45 | 38 | 12 | 31.26 | 50.38 | 836 | 6.55 |

| 300/18 | 300 | 100 | 1.75 | 38 | 12 | 31.04 | 50.05 | 1005 | 7.88 |

| 300/24 | 300 | 100 | 2.4 | 38 | 12 | 30.56 | 49.34 | 1366 | 10.71 |

| 300/30 | 300 | 100 | 3 | 38 | 12 | 30.12 | 48.69 | 1695 | 13.29 |

| 350/18 | 350 | 100 | 1.75 | 43 | 12 | 29.65 | 49.32 | 1110 | 8.70 |

| 350/24 | 350 | 100 | 2.4 | 43 | 12 | 29.20 | 48.64 | 1510 | 11.84 |

| 350/30 | 350 | 100 | 3 | 43 | 12 | 28.78 | 48.01 | 1875 | 14.70 |

| 400/20 | 400 | 100 | 1.95 | 48 | 12 | 28.37 | 48.48 | 1351 | 10.59 |

| 400/24 | 400 | 100 | 2.4 | 48 | 12 | 28.07 | 44.03 | 1654 | 12.97 |

| 400/30 | 400 | 100 | 3 | 48 | 12 | 27.67 | 47.42 | 2055 | 16.11 |

Steel Thickness, Grade, and Zinc Weight

| Steel Thickness | Grade | Zinc Weight |

|---|---|---|

| 1.15 – 1.45mm | G500 (MPa) | 275 g/m² |

| 1.75 – 3.0mm | G450 (MPa) | 275 g/m² |

Tolerances

| Web Depth ± 2mm | Flange Width ± 2mm |

| Lip ± 1mm | Hole Centers ± 1.5mm |

| Web/Flange Angle 88-93° | Length ± 3mm |

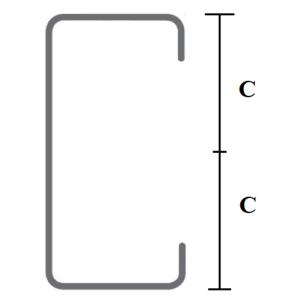

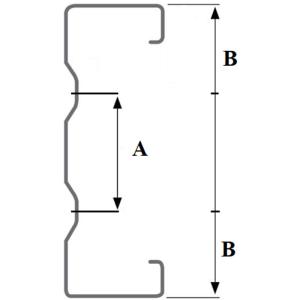

Hole Sizes

Pre-punched holes can be provided.

| Hole Sizes: | Ø14 | Ø18 |

| slotted 14-18 | slotted 18-22 |

| Purlin Size | A | B | C |

|---|---|---|---|

| HST100 | - | - | 50 |

| HST150 | 80 | 35 | 75 |

| HST200 | 120 | 40 | 100 |

| HST250 | 160 | 45 | : |

| HST300 | 200 | 50 | 150 |

| HST350 | 240 | 55 | 575 |

| HST400 | 280 | 60 | 200 |

Design Information

HST Purlin and Girt loads are presented in Limit State format consistent with AS/NZS 1170.0:2002 “Structural Design Actions”. All design information² should be used in conjunction with AS/NZS 4600:2005.

Design Criteria

Strength reduction factors are included in the design load capacity and have been determined from AS/NZS4600:2005 as follows:

Bending fb = 0.90 (fb = 0.95 for section moment capacity)

Compression fc = 0.85

Shear fv = 0.90

The self-weight of HST purlin is not included in the load tables and should be calculated along with other dead loads.