Steel & Tube HST Top Hat sections are an economical option. They are lightweight, versatile, and an easy to use product that can be used for roof purlins, wall girts and floor joists.

HST Top Hats are manufactured from high strength Z275 galvanised steel coil in accordance with AS 1397 that provides good protection in most exposed internal environments. They are ready for use in smaller spanning applications from 3m to 7m.

Contact with materials not compatible with zinc should be avoided.

Interested in hearing about future promotions? Sign-up to be kept updated!

HST Top Hats

HST Top Hat purlins are manufactured from hot dipped galvanised steel with a coating weight of 275 gram/sqm, in line with other common lightweight steel structural building products.

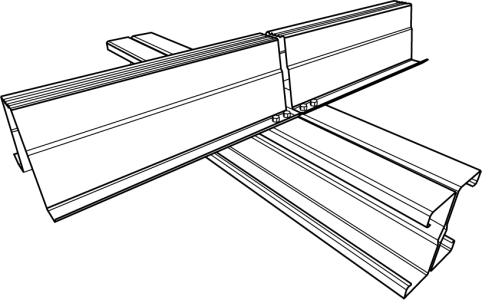

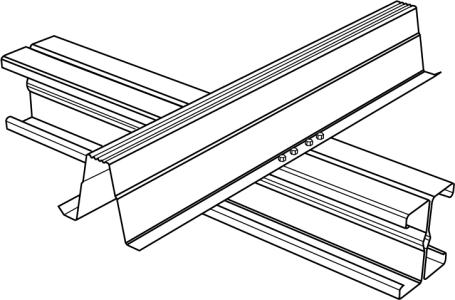

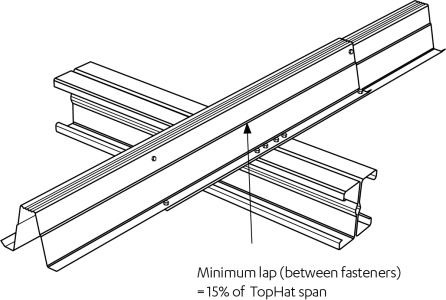

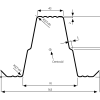

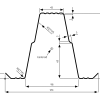

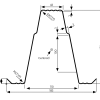

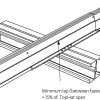

HST Top Hat purlins are easy to use as they fasten directly to their supports, resulting in a saving on cleats. The symmetrical section means there are no requirements for braces or nogs to prevent twisting and the profile is easily lapped for optimal performance.

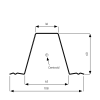

HST Top Hats come in a full range of sizes from 60mm to 150mm depth, are easy to use, and screw directly to the supports without the need for purlin bracing and cleats.

| Steel Thickness, Grade and Zinc Weight | |||

|---|---|---|---|

| Steel Thickness T(BMT) MM | Steel Grade | Yield Strength Fy(MPa) | Zinc Weight Z(g/m²) |

| 0.75 | G550 | 550 | 275 |

| 0.95 | G550 | 550 | 275 |

| 1.15 | G500 | 500 | 275 |

| Tolerances | |||

|---|---|---|---|

| Length | ±6mm | ||

| Depth/Width | 60 Top Hat purlin: ±1mm 100/120 Top Hat purlin: ±2mm 150 Top Hat purlin: ±3mm | ||

| Top Flange Width | ±1mm | ||

Lengths

HST Top Hat sections are available in long run lengths up to 12 metres, depending on the available transport and handling facilities.

Design Information

The HST Top Hat Purlin System does not require bracing to provide restraint. The typical spans are designed to give information for preliminary design and costing and are based on the factors noted.

Handling and Storage

HST Top Hat sections must be kept dry during transportation and storage as water between the stacked sections will cause premature corrosion. If it gets wet, it is recommended to separate and stack openly to allow for ventilation to dry the surface. Cutting, if required, should be done with a shear or hacksaw, use of abrasive disc blades is not recommended.

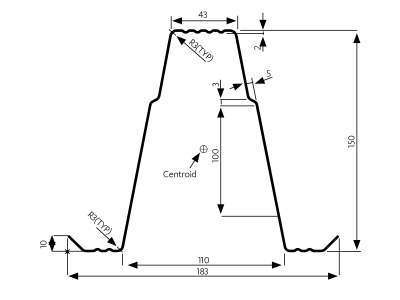

| Tophats Size | Product Chart | Height (mm) | Material Thickness (mm) | Lengths Available | kg per m |

|---|---|---|---|---|---|

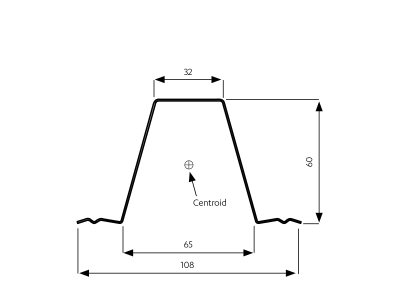

| HST 60 | 60 x 0.75mm 60 x 0.95mm | 60 60 | 0.75 0.95 | Run to Order Run to Order | 1.225 1.531 |

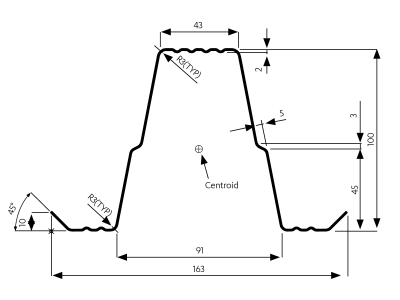

| HST 100 | 100 x 0.75mm 100 x 0.95mm | 100 100 | 0.75 0.95 | Run to Order Run to Order | 1.947 2.434 |

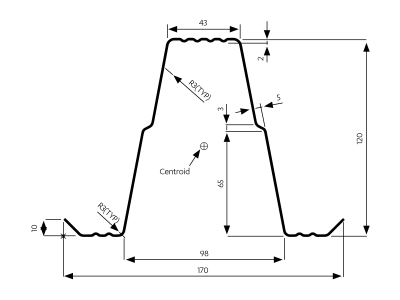

| HST 120 | 120 x 0.75mm 120 x 0.95mm | 120 120 | 0.75 0.95 | Run to Order Run to Order | 2.198 2.748 |

| HST 150 | 150 x 0.95mm 150 x 1.15mm | 150 150 | 0.95 1.15 | Run to Order Run to Order | 3.219 3.862 |

| 150 x 1.55mm | 150 | 1.55 | Run to Order | 5.23 |