The ComFlor® composite floor decks range continues to set new standards in construction technology across New Zealand and is one of the market leaders in composite steel flooring systems.

ComFlor is manufactured in New Zealand by Steel & Tube under license from Tata Steel UK.

Interested in hearing about future promotions? Sign-up to be kept updated!

Composite Floor Decks Ltd

Rethinking Construction

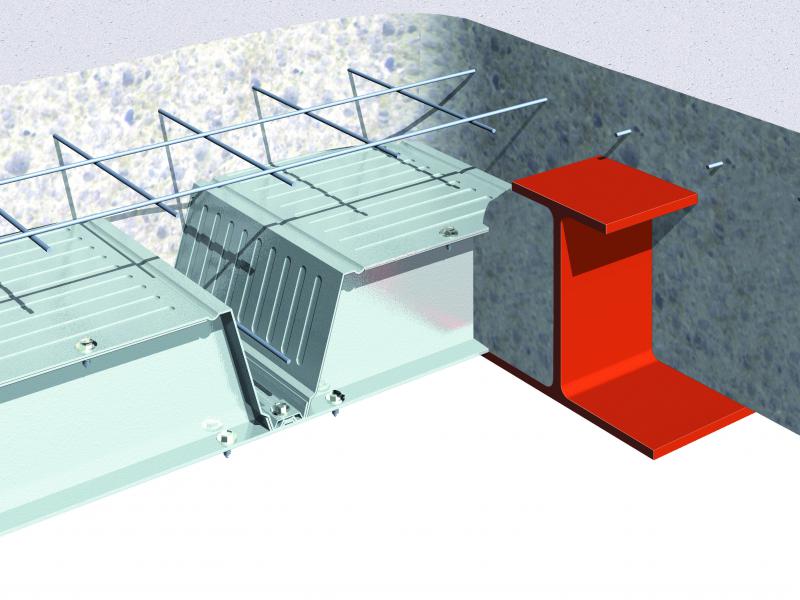

Composite Floor Decks LTD (CFDL) is a market leader in the design, installation and stud welding of steel floor decking systems, including ComFlor.

Incorporated in 2004 and now owned and operated by Steel & Tube who have enhanced the supply chain capabilities and created an end-to-end process from manufacturing through to installation. For us, quality is at the heart of everything we do. From the sourcing and production of high-quality products, through to customer service and installation, we offer a comprehensive service to the construction industry.

CFDL Services Include:

- Supply of steel decking flooring systems, manufacturing to customer requirements

- On-site installation and delivery across New Zealand including steel decking flooring systems, stud welding and safety netting

- Technical detailing and draughting expertise providing project specific designs

- Computer-generated drawings including 3D modelling using AutoCAD LT / Vectorworks/BIM360

- End-to-end contract management

- Quality management team providing traceable and auditable records

- Comprehensive product range

What are the benefits to a composite steel flooring system?

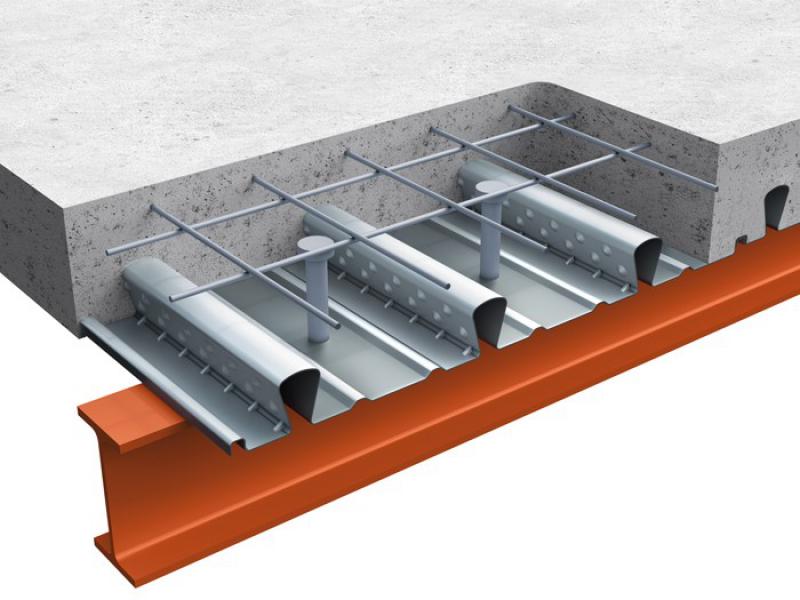

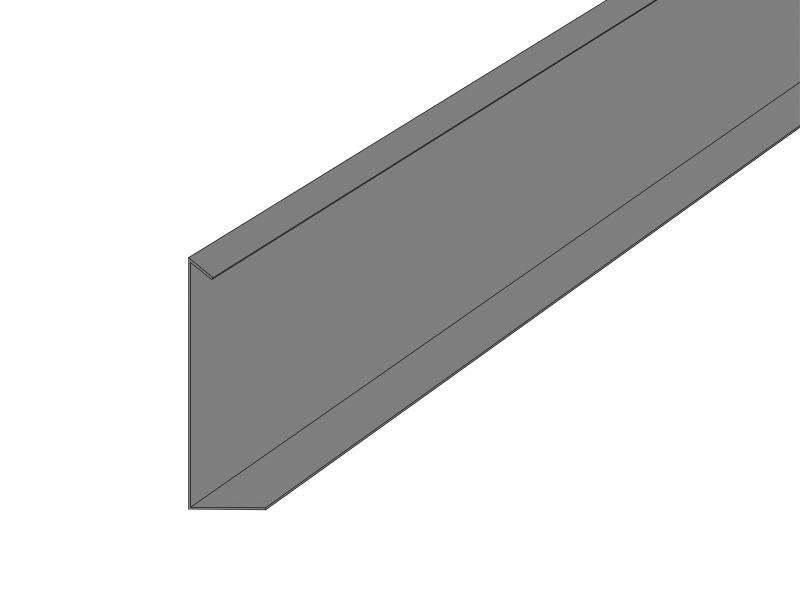

Composite steel flooring systems offer superior performance, efficiency, structural integrity, weight, height, fire rating, simplicity, and ease of construction. ComFlor® composite floor decks are lightweight and easy to handle, providing a safe working platform, construction stage bracing, and cost-efficient construction.

For all sales enquries please phone 0508 332546 or email [email protected]

Product Guides

ComFlor® SR Design Information

ComFlor® 60 Product Guide (PDF)

ComFlor® 80 Product Guide (PDF)

ComFlor® 210 Product Guide (PDF)

Durability and Environment

![]() ComFlor Residential Building Durability Statement Jan 2023 (PDF)

ComFlor Residential Building Durability Statement Jan 2023 (PDF)

![]() ComFlor Commercial Carpark Durability Statement Jan 2023 (PDF)

ComFlor Commercial Carpark Durability Statement Jan 2023 (PDF)

![]() ComFlor Environmental Choice Certificate March 2023 (PDF)

ComFlor Environmental Choice Certificate March 2023 (PDF)

Acoustic

![]() Hegley Acoustic Report April 2019 (PDF)

Hegley Acoustic Report April 2019 (PDF)

Fire

Fire Assessment Report Fire Test Report exova 14 May 2018 (PDF)

GIB Fire Rated Systems Supplement Feb 2020 (PDF)

Superior Performance

As you would expect a highly designed and tested construction profile from one of the world’s leading innovative metals companies has numerous advantages over conventional flooring methods and the direct competition:

Superior Performance

The ComFlor® range of profiles are arguably the most efficient currently available anywhere in the world:Span

Our profiles have the best span of any steel decking in New Zealand. Better spans means fewer beams are required to support the structure.Efficient

Due to the intrinsic efficiency of composite construction and the displacement of concrete by the profile shape, considerably less concrete is used than in conventional reinforced concrete construction. This reduces the size and cost of elements used in the primary structure and the foundations.Structural integrity

Elimination of temporary propping during construction, leaves the structure with better long term structural integrity, and improves crack control in the slab.Weight

Reduced weight relative to competing systems provides advantages in seismic, gravity and foundation design.Height

Composite beams use the slab as a compression element, which increases stiffness and reduces their size. These savings translate to a reduced floor zone and therefore a reduced overall inter-storey height, allowing the possibility of additional revenue generating floors being added.Fire

Extensive testing and fire engineering work by The Steel Construction Institute have resulted in fire ratings of up to four hours being available with the use of light mesh within the composite slab and no protection to the deck.

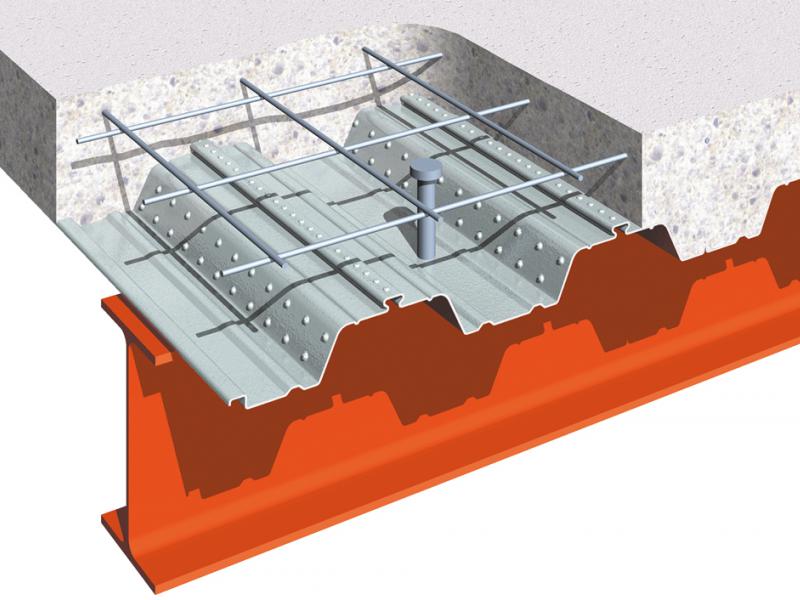

Simplicity (Ease of Construction)

ComFlor® is very simple and fast to install:

Speed

Large bundles of up to 110m2 of deck can be rapidly craned into position, reducing traffic disruption and overcoming ground level storage issues. 400m2 can be laid, trimmed, and stud welded by one team per day. And with minimal mesh reinforcement and pumped concrete, the completed floor can quickly follow.Props eliminated

Temporary props can usually be eliminated. Superior design typically means propping is not required. The result is faster erection and a shortening of the construction programme.Lightweight and easy to handle

ComFlor® is light weight and easy to handle, even into difficult to access zones. Two workers are able to lift and install 12.00 metre sheets.Working Platform

Once laid, the deck acts as a safe working platform for all subsequent subtrades and as a safety barrier to overhead hazards.Construction Stage Bracing

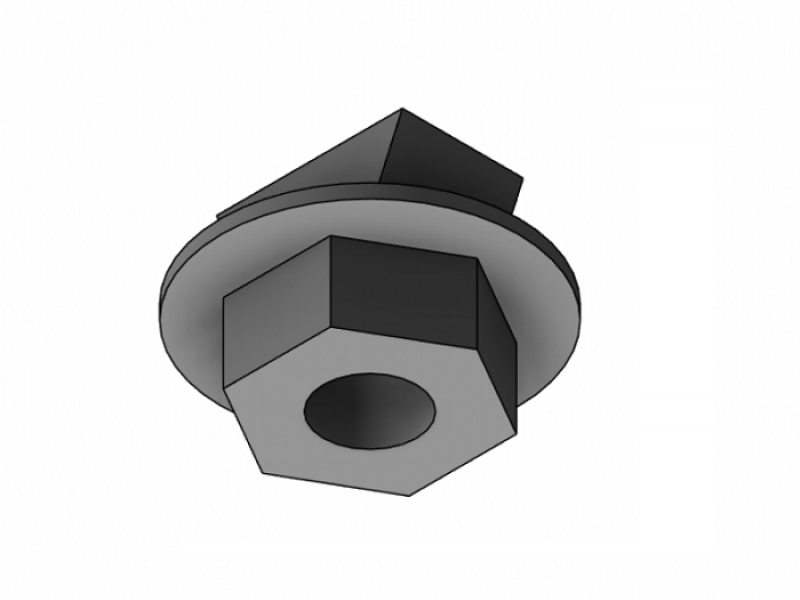

The deck acts as a lateral restraint and forms a diaphragm, transmitting wind load from the outer steelwork to the core. Therefore once the decking is fixed, it contributes significantly to the stability of the structure.Good for services

ComFlor® composite floor decks incorporate systems for the easy attachment of suspended services, negating the requirement to fix into concrete. Slab penetrations up to 300mm can be formed without the need for additional reinforcing. Larger openings can be incorporated with the use of additional reinforcing or structural steel.

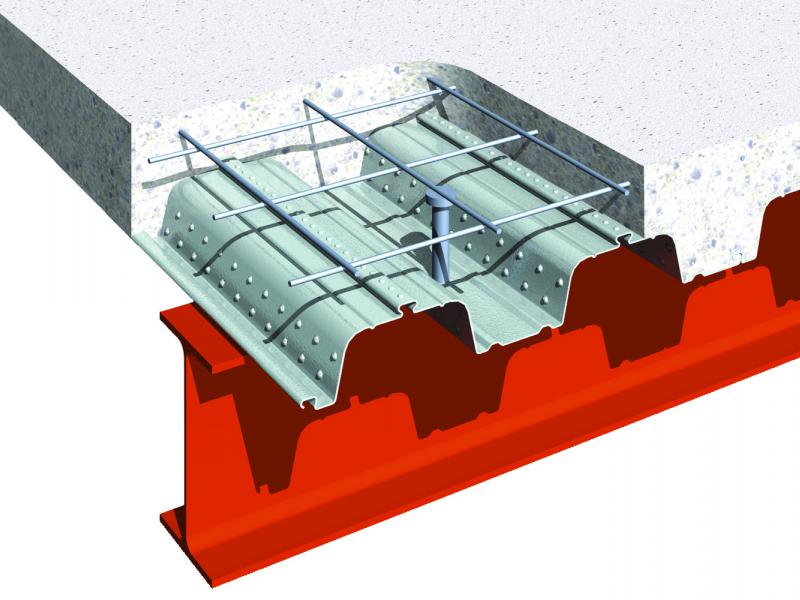

Cost efficient construction

ComFlor® is the most cost efficient mid-floor solution available:

Gauge options

ComFlor 80 and ComFlor 60 are available in a range of gauges from 0.75mm to 1.2mm so that the deck thickness can be optimised to the project requirements, minimising the cost of the deck.Less structural components required

Longer spans with fewer beams means a more cost effective build.No propping

Elimination of the need for temporary propping saves money on the cost of propping and minimising mesh, while enhancing crack control in the slab.Faster rental returns

The speed of ComFlor® compresses the construction programme meaning that tenants can move into the building earlier giving faster rental return.Less additional cost

ComFlor’s unique shape reduces construction deflections, minimising concrete usage and leading to substantial savings on large projects. A high inherent fire rating often means additional fire protection, and the associated cost, is not required.

Sustainable construction

ComFlor® is a very sustainable solution:

Local content

The coil is sourced from New Zealand steel using locally sourced iron sands – reducing transport and handling impacts.Recycled content

Twelve percent recycled material is used in the manufacture of ComFlor® coil stock.Energy efficient

The composite nature of the steel used with concrete means the ongoing benefits of thermal mass can be utilised to stabilise temperatures in the living environment and minimise energy use.Recyclable

The steel used in ComFlor® is fully recyclable at the end of the building’s life.

Testing

ComFlor®’s profiles are thoroughly tested so you can have confidence they will perform.

UK testing

All ComFlor® profiles have been tested by Imperial College London. This preeminent institution carries out an extensive range of recognised laboratory tests to derive values for the construction and composite stage. This testing has been independently verified by the United Kingdom’s Steel Construction Institute.New Zealand testing

Steel & Tube has carried out our own independent construction stage tests to verify the work done in the United Kingdom and to test the profile versus competitors in this country. The New Zealand testing found that ComFlor was the strongest profile available in this country at the construction stage.Fire testing

Full fire testing has been carried out by Warrington University of the United Kingdom.

Why Steel?

Over the last twenty to thirty years the popularity of steel framed construction has grown the world over. This growth has manifested itself in New Zealand too, with structural steel growing from 15% in 1999 to represent 50% in 2008.

There have been a number of causes of this global growth including:

- Reduced weight: Steel is a lighter method of construction, relative to traditional alternatives, allowing for smaller foundation size and taller buildings.

- Manufacturing capacity: Production volumes of 500m2 per hour, 24 hours a day if required.

- Short manufacturing lead times: Leading to faster delivery to site.

- Shorter construction time on site: Often months can be shared from construction time tables.

- Numerous advantages on restricted sites: Bundles can contain 110m2 and can be loaded directly onto the structure ready for hand installation.

- Reduced craneage time: One truck can carry 900m2 and individual bundles are approx. 50 m2

- Increased flexibility of construction methodology: Including ‘Up/ Up construction’, where several floors are constructed at once and ‘Top Down construction’, where ground level bracing floors are put in place then construction commences above and below ground at the same time.

For more information on the benefits of steel please call us on 09 271 1780.

Additional information can also be gathered at www.scnz.org